The modern hazmat cleanup process benefits from a myriad of technological advancements that make it safer, more efficient, and more environmentally friendly.

In the last few decades, the face of hazmat cleanup has transformed dramatically. Once a high-risk and labor-intensive operation, the modern hazmat cleanup process benefits from a myriad of technological advancements that make it safer, more efficient, and more environmentally friendly. In this comprehensive exploration, we'll deep-dive into how innovative technology, from drones to advanced robotics, is revolutionizing every stage of hazardous material cleanup.

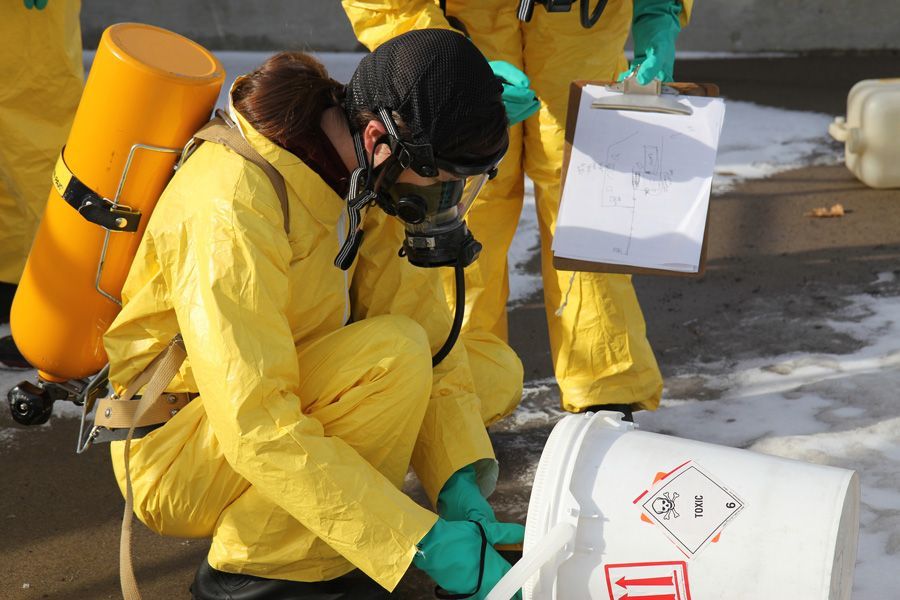

When we talk about hazmat cleanup, the words themselves evoke scenes of disaster and danger. Indeed, the management and disposal of hazardous materials require precision, care, and often, specialized training. Traditionally, tasks such as identifying, containing, and removing hazardous materials have been carried out by teams of brave individuals, equipped with personal protective gear, and a careful plan. While human expertise is irreplaceable, technology has carved out a new frontier in this industry, offering tools that can manage risk, increase speed, and lower costs.

The Evolution of Detection and Identification Technology

Before hazardous materials can be cleaned up, they need to be found. This is where detection and identification technologies come into play, evolving from simple handheld devices to state-of-the-art systems capable of mobile, remote, and airborne operations.

Portable Mass Spectrometers and Emerging Analytical Tools

Imagine the first responders of yesteryear carrying bulky, stationary mass spectrometers. Today, portability is the buzzword as devices have been miniaturized and made handheld, enabling field analysis with immediate results. Emerging analytical tools like nanosensors and microfluidic chips are at the forefront of detecting even the most minute traces of hazardous materials.

Remote Sensing for Large Area Scans

For outdoor areas or expansive facilities, remote sensing tools have become invaluable. Satellite imagery, LIDAR (Light Detection and Ranging), and various types of sensors mounted on aircraft can scan large areas, identifying potential hazards before a cleanup operation begins.

Cutting-Edge Containment and Removal Technologies

Once a hazard is identified, containing and removing it is the next critical step. With the introduction of cutting-edge technologies, this phase is now more efficient and less intrusive than ever before.

Automated and Robotic Systems

Robots have taken on some of the toughest tasks in hazmat management. From crawling into confined spaces to handle radioactive materials to rovers that can traverse hazardous environments, robots can handle the most dangerous materials without putting humans at risk.

Advanced Drone Systems

Unmanned aerial vehicles (UAVs) or drones, equipped with specialized sensors, cameras, and sometimes even robotic arms, can fly into areas deemed too hazardous for humans, scouting, and sometimes even beginning the cleanup process.

Managing a hazmat incident often comes down to time. The quicker you can identify and address a hazard, the less risk it poses to the public and the environment. Emerging technologies are drastically increasing the speed at which hazardous materials are managed, offering a form of agility that was simply not possible before their advent.

Real-Time Data for Decision making

With emerging sensor networks and the Internet of Things (IoT), data on hazardous materials is gathered at unprecedented rates. This influx of information leads to smarter, more informed decisions in the field.

Enterprise Software Solutions for Hazardous Material Tracking

Powerful enterprise software tools provide a centralized platform for tracking hazardous materials, streamlining communication across cleanup teams and stakeholders. These platforms offer real-time updates, ensuring that everyone involved is working from the latest data.

Machine Learning and AI for Predictive Modeling

The use of artificial intelligence and machine learning is not limited to other sectors. In hazmat cleanup, these technologies are becoming capable of predictive modeling. They can anticipate the behavior of hazardous materials, the flow of contaminants, and the potential risks associated with different cleanup approaches.

The Human Element in a High-Tech World

While technology is playing an increasingly pivotal role in hazmat cleanup, it is not without its challenges. Deploying and maintaining advanced systems require a workforce that is not only comfortable with technology but also capable of troubleshooting and adapting to unexpected circumstances.

Training the Next-Generation Hazmat Cleanup Specialists

Technical skill development must now include a robust understanding of the various technologies used in hazmat cleanup, alongside traditional safety and cleanup techniques. This comprehensive training ensures that future responders are prepared to leverage all tools at their disposal.

Balancing Technology and Human Intervention

It is important to remember that technology is a support system for human intervention, not a complete replacement. The best outcomes are achieved when technology and human expertise work in concert, enforcing each other’s strengths and mitigating their weaknesses.

Environmental Impact and Sustainability

Hazmat cleanup is not only about removing the immediate threat but also about doing so in a manner that does not create long-term environmental issues. The recent advancements in technology are also shaping the field to be more sustainable and environmentally conscious.

Using Greener Technologies for Cleanup Operations

From the chemicals used in decontamination processes to the fuels that power cleanup vehicles, there is a growing focus on green and sustainable technologies in the hazmat industry. Bio-remediation, for example, is a process where microorganisms are used to neutralize hazardous materials, reducing the need for heavy industrial cleanup efforts.

Monitoring and Reporting to Evaluate Cleanup Effectiveness

The environmental impact of a hazmat cleanup operation must be evaluated and reported upon. Technology is vital in this role, providing continuous monitoring and detailed reporting on the effectiveness of cleanup efforts and any residual environmental risks.

Beyond Cleanup - Integrating With a Circular Economy

The future of waste management, including hazardous material cleanup, points towards a circular economy where waste is minimized, resources are conserved, and value is created. Technology is instrumental in this transition, facilitating the recovery, recycling, and repurposing of hazardous materials.

Resource Recovery and Material Reclamation Technologies

Innovations in material reclamation are making it more possible than ever to extract and reuse valuable or rare materials from hazardous wastes. Sophisticated separation techniques and material-specific recovery processes are reducing the need for landfill disposal.

Designing Waste Minimization Into Industrial Processes

An integrated approach to the life cycle of hazardous materials—where waste minimization is designed into industrial processes—requires a deep understanding of the materials involved. Technology is assisting in this design by providing insights into the composition, usage, and potential for recycling of hazardous materials.

Conclusion

The role of technology in enhancing hazmat cleanup efforts is one of progress, potential, and transformation. From the early detection and identification of hazards to the containment, removal, and aftermath management, the impact of technological innovation cannot be overstated. While the hazmat cleanup sector remains a high-stakes environment, ongoing advancements are continuously raising the bar for what is possible, promising a future where hazardous materials are managed with unprecedented safety, efficiency, and thoughtfulness towards our environment and communities. With each new breakthrough, we move closer to a world where the threat of hazardous materials is tackled not with trepidation, but with the confidence that comes from having the best tools at our disposal.